Continuous developments regarding the efficiency and sustainability of buildings have increased the need to energetically adapt building envelopes. The facade, as a frontier element between the air-conditioned internal space and the external environment, plays a fundamental role in the indoor / outdoor heat exchange, significantly affecting the overall thermal comfort of a building.

The systems of ventilated facades in aluminium represent an interesting solution to face the problems of energy efficiency through a sustainable approach. The use of ventilated facade systems in aluminium has increased, in recent years, thanks to its ability to improve energy saving and humidity control performance, as well as, for ease of installation and maintenance, for good resistance to different environmental conditions and for its innovative and contemporary visual impact.

THE VENTILATED FACADE: A CONSOLIDATED SYSTEM

The natural ventilation wall is a long-established technological system. It is believed that it can date back to the 1700s, when the need to repair and preserve building materials exposed to the elements was necessary.

Originally, the system provided for an external coating of natural material, mechanically connected to wooden supports, anchored once again mechanically to the external wall of the building. Despite the rudimentary and coarse techniques used in previous centuries, this system was able to fulfil the need to protect the external vertical wall from the elements, thus improving the situations of possible condensation formation.

Driven also by the growing need to reduce energy consumption, in the 70s in northern Europe and in the 80s in Italy, the construction sector magazines began to disseminate information on construction principles, quality and performance results. From the publications of the time, a technological system is presented having a series of functional layers connected to the building by means of a metal substructure.

The system layering included: a layer of thermal insulation placed in adherence to the external wall of the building, below, a ventilation gap and the external coating finish. Since then the system has not changed much in its operation.

Source: https://www.archiproducts.com/de/produkte/kme-architectural-solutions/dach-metallpaneel-und-profilplatte-tecu-classic_1096

FUNCTIONING OF THE VENTILATED FACADE: OUTLINE OF TECHNICAL PHYSICS

In the space of the cavity, a natural ventilation mechanism is triggered, thanks to the entry of the ascending airflow, activated by the thermal difference between the temperature of the cavity and the inlet, by means of ventilation vents located at the base of the facade and at its upper end. This phenomenon, also called the “chimney effect” is characterised by a flow of air that is regulated according to the external environmental conditions. In fact, in summer, the system allows for a reduction of the incoming thermal load, while in winter the goal is to limit the heat losses present inside the buildings. The function of the external cladding layer, in addition to physically creating the cavity space, is to protect the internal layers from the action of atmospheric agents.

In order to be efficient, i.e. to trigger convective motions that improve the comfort conditions of the building, the distance that separates the two layers must always be designed, taking into account a series of factors related to the climatic conditions in which the building is located. The building, its exposure, and the morphology of the building itself, (shape, size, number of floors).

A STARTING POINT FOR THE DESIGN OF NZEB BUILDINGS

Seemingly it may seem like a simple succession of layers, but in reality the ventilated facade system requires careful planning. Only after specific assessments and performance analyses is it possible to choose the right insulation, the appropriate size of the cavity, or the ventilation vents. The project must be studied in detail. However, if it is entrusted to specialists and everything is carried out in a workmanlike manner, the advantages are multiple and considerable. For example, improving the thermo-hygrometric behaviour through the elimination of thermal bridges, increasing the thermal inertia of the external walls and eliminating the condensation, are fundamental principles to improve the comfort of indoor environments, with the consequent reduction of energy consumption and maintenance and renovation costs. In fact, protecting the building from the action of atmospheric agents contributes to increasing the longevity of the building.

A properly designed casing can transform a building from energy-intensive to passive or, as better defined by law, a Nearly Zero Energy Building (nZEB).

Source: https://www.pinterest.it/

THE SYSTEM AND FUNCTIONAL LAYERS

The system can be installed on new buildings or in buildings that require an energy requalification or that have an external envelope to be restored, improving in any case the thermo-hygrometric performance and respecting the requirements of the current regulations.

The ventilated facade is a dry-made system, which provides for mechanical assembly between the different layers, ensuring rapid installation and ease of maintenance, such as to make it possible to replace each single element or larger portions of the facade, in a short time.

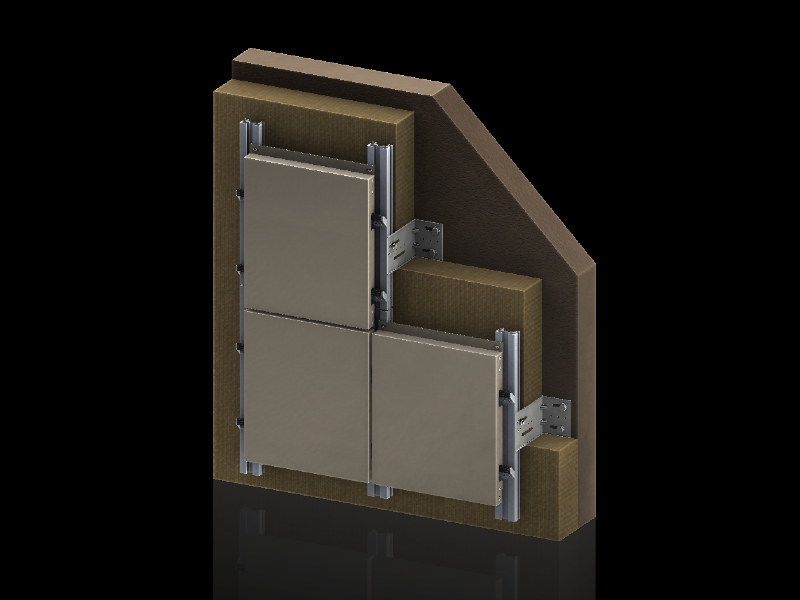

The ventilated facade is composed of the following functional layers listed, starting from the inside:

- Load-bearing layer, this is the external wall of the building, it is necessary to support the entire system that will be installed in front;

- Thermal insulation layer, the insulating materials can be of different nature, natural or chemical, in both cases the panel insulation will be installed on the external surface of the infill by means of a mechanical fixing system, the anchor;

- Ventilation layer, has a size ranging from 30 to 100 mm thick, is the necessary space of discontinuity between the cladding and the packet that constitutes the load-bearing layer, it must be designed in such a way as to trigger the phenomenon of “effect chimney”;

- Sub-structure, permits the mechanical support the external covering, made with uprights and crosspieces or point fixing, generally in metal or wood, supported by an anchoring system connected directly to the load-bearing infill layer;

- Cladding layer, made up of panels, slabs or cladding elements of different types, materials, shapes, finishes and colours, installed thanks to the anchoring systems fixed to the load-bearing layer, the cladding can be made of brick, natural stone, stoneware, in glass, in metallic materials (e.g. steel, aluminium, copper, titanium, zinc-titanium), or in composite material of different nature.

THE IMPORTANCE OF ALUMINIUM CLADDING IN VENTILATED FACADE SYSTEMS

The external cladding of the buildings therefore plays a fundamental role in contemporary architecture, since in addition to performing the function of protection from atmospheric agents, they also define the formal character of the building. For this reason, it is necessary to reconcile the various aesthetic, durability, environmental sustainability and energy saving needs, also taking into account the costs, in proportion to the duration of the product applied.

Specifically, the external cladding layer of a building must resist mechanical stresses, such as wind and rain, corrosive phenomena in the specific case of metals, seasonal temperature fluctuations, which cause thermal expansion of the elements, as well as surface or interstitial condensation phenomena of the external wall.

The diffusion of aluminium as a cladding material takes place thanks to its extraordinary characteristics of lightness, hardness, good plasticity and formability, qualities that permit obtaining different products, suitable for any type of design complexity, as well as minimum dimensional tolerances, precision and assembly speed.

Used in external cladding, or as a finishing layer for ventilated facades thanks to its high resistance to atmospheric agents and corrosion: Indeed, aluminium in contact with oxygen is passive, covering itself with oxide and protecting itself from corrosion problems.

IN CONCLUSION

The ventilated facade system in aluminium today is the most complete and energy-efficient technological solution to achieve the objectives of a building’s thermo-hygrometric well-being. By distancing itself with an additional layer ventilated by the facing wall, protection from atmospheric agents can be guaranteed, especially from the infiltration of rainwater, the latter of which causes the greatest problems of degradation of the building.

The insulating layer, associated with the ventilated cavity, reduces energy consumption both for winter heating and for summer cooling, ensuring excellent operation in all seasons. In summer, overheating of the walls is prevented through effective ventilation in the interspace, while in winter, the still air of the interspace acts as an additional natural thermal pad.